News

swepro Group optimises production

01.06.2016

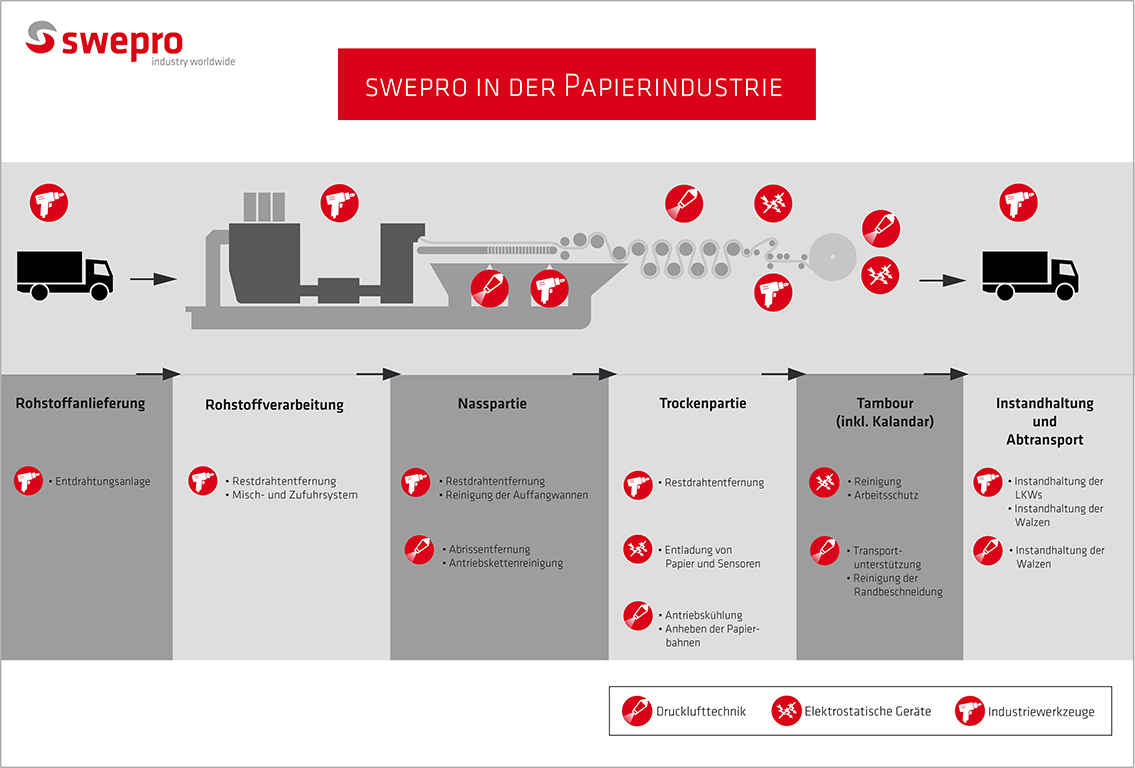

This specialist optimises the processes in paper manufacture from cleaning to maintenance with its air and water nozzles, powerful tools and electrostatic products.

The fibre felt undergoes many individual processes during the manufacture of paper. Specialist machines and equipment is required in order to carry out all the steps as efficiently as possible. This is where the numerous products of the swepro Group are used. Besides the professional air and water nozzles, swepro’s electrostatic products also contribute to a substantial improvement of the individual processes. In addition to this the efficient industrial tools by the swepro Group are also used in production improvement at the paper mill. Individual solutions can also be found in the swepro Group range for the maintenance of the different devices that are used for paper manufacture. Finally the range of products supports all the cleaning, moistening, transportation and repair processes that are necessary to manufacture the paper in the approximately 150 m paper machine. The result is a paper roll that is optimised for further processing.

Comprehensive range of products allows optimal application

We differentiate between a wet and a dry section in the paper manufacturing process and the design of the paper machine. The raw materials are mixed before the wet section. The swepro Group is an important partner in the manufacturing process with its tools that are specifically adapted for this industry. This means, for example, that tools can be used to easily carry out the de-wiring of the raw material. The raw materials are delivered wrapped in a wire that must be completely removed without fail to allow the manufacture of a perfect end product. The paper web then needs to be constantly moistened in the wet section. The swepro water nozzles are used in this area because they spray water onto the paper web in a reliable, targeted and contactless manner. It is only possible to avoid the paper web tearing due to excess moistening at certain points if the application is controlled.

In the corresponding sieving and pressing section it is important that the processes are carried out evenly in order to provide additional protection against tearing of the paper web. In order to do this, the drive chains and the sieves on the paper machines must be optimally cleaned in these sections. The swepro Group recommends SILVENT compressed air nozzles for this purpose because they also clean places that are difficult to access in a powerful, reliable and energy efficient manner. In the subsequent dry section it is not only possible to carry out cleaning processes with the help of the targeted use of compressed air but also to cool the drive machine in the system. This is the only way in which a smooth manufacturing process can be maintained. Specially adapted electrostatic products from the swepro Group are used so that the charge that is constantly created by the rolling of the paper can be discharged in a controlled manner. This both prevents the material from adhering to itself, which could lead to faults in the production process and reduction of the production quality, and also counteracts painful discharges to the production staff at the paper mill.

Increased efficiency through individual repair options

The swepro Group provides immediate solutions for many production steps and necessary repairs with its comprehensive range of specialist tools. Both the technical maintenance of the important rolling mill and repairs in the internal locksmith’s department can be mastered with these specialist tools. This ability to take fast action means that production stoppages are lessened in an emergency. In turn this greatly reduces economic losses caused by faults. And when the vehicle fleet is put to use for delivery after completion of the paper roll production then the swepro Group can continue its customer support. Thus the company aids the paper production in an uncomplicated and efficient way with its range of top quality technology and tools and displays once again the wide range of uses for its products.

>>info-chart